02.06.20

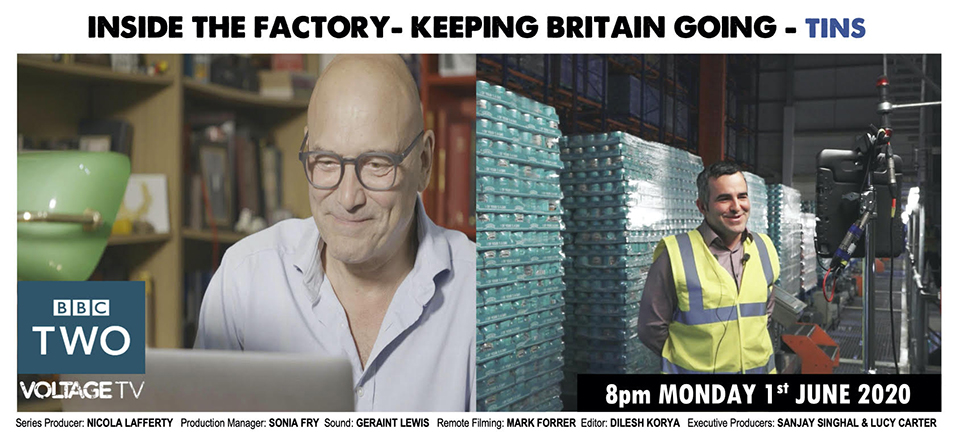

"Inside The Factory: Keeping Britain Going" Working During the Pandemic.

With the second episode of Inside the Factory: Keeping Britain Going TX’ing on Monday night I thought I’d share a little bit of what went on behind the scenes, and predominantly, OUTSIDE the factory on the shoot day.

For those that haven’t watched the show, Inside the Factory see’s Gregg Wallace visit some of the biggest Factories in the UK and Europe to see how our favourite everyday items are made and the effort, expertise, technology and logistics that go into making them. I.T.F can be hard work at the best of times for a sound recordist as I have discovered over 4 years shooting the programme.

When ITF had a Special commissioned during lockdown with the working Title “Inside the Factory: Keeping Britain Going” the first place we would visit would be the Essity factory in Manchester that makes Cushelle Toilet paper and Bounty Kitchen towel. Having been on the shoot in 2018 I knew all the usual stumbling blocks would be there with the added detail of presenter-contributor chats being done remotely no access granted to the factory for Voltage TV production crew. In a “normal” episode Gregg Wallace walks the floor of the factory seeing what goes into making our star product and meeting the people that make it. This time round, with a real visit out of the question, the special would revisit Essity and the team that had been focus of that previous episode in the main series. We’d see how Lockdown had affected production, staff at the factory and the procedures that had been brought in to keep the factory working during the Pandemic and the staff safe while doing so.

On location at Good’s in @ Essity Factory

Gregg would be skyping the factory from his sofa. Whilst Skype chats have become very common

place on television during lockdown there were some particular challenges that would set ITF apart. Most Skype chats that have made it to air take place from studio to living room and back. ITF would be chatting from living room to factory floor. ITF needs to have some depth on the Skype shot so Gregg can see what’s happening around our contributor, little point in taking us to these specific locations otherwise. ITF producers, Voltage TV, didn’t want it just to feel like a sit-down interview with Gregg and factory team member, intercut with GV’s. Voltage TV wanted to keep the style of the original episodes and feel like we were back, immersed, in the factory. As well as Skype there’s an element of us being taken round the factory by one the “Guides” showing us different elements of the effect on day to day running. A roving reporter style moment. This would be shot conventionally and the cameras for this would also offer a non-sync, release shot on the Skype chat.

Sony X70 on location, shooting wide shot of the Skype chat at the Heinz factory for the Baked Beans Episode

The solution had to have fail safes. We had to have a couple of recorded options. The contributors would have a radio mic, a body recorder, an IEM each and, where required, a Peltor headset (affectionately now called “Mickey Mouse Ears”), these are something akin to what you see in the pitlane on the F1for comms between team and driver, perfect for noisy environments but a little hefty. The Peltors would have a body recorder added to their headphone and mic. The radio mics would feed a receiver, which would feed the tablet, sending the factory side of the conversation through Skype to Gregg. Greggs audio would come out of the tablet, into a transmitter, to the IEM net for the Factory contributors. The second camera (Sony X70) shooting a wider shot – again, set up by the “Our Man on the Inside”. The radio mic connected to the Skype chat was purely for the Skype comms, the “Programme Sound” was being recorded by the Zaxcom body recorder. The option of sending audio to one of the X70’s didn’t make much sense as no one would be monitoring there and would probably just complicated things unduly. The Gregg Crew were shooting Greggs reactions and questions to the factory obviously, but also recording the laptop screen via HDMI onto an Atomos Ninja. This was another back up, as for most of the chats it was the only image and sound that could be monitored outside of the factory. Master timecode was fed to the Zaxcom and a digislate. We had to use a digislate for the X70’s in the factory as that camera doesn’t have a designated timecode track.

When the Skype call connected the slate would go in for the x70 at the factory and then in for the tablet so that the crew with Gregg could get a reference timecode. The digislate was the way of linking their footage and our footage with timecode. At the factory, the digislate was jammed to the same timecode as the Zaxcom body recorders, I would have preferred to have had timecode being sent to one of the audio tracks on both of the X70s, just to take some pressure off the digislate being used properly but we discovered that the app that Post production are using to remote monitor in the edit doesn’t like it and it just sits as a distraction in the audio channels.

Atomos recording the Skype feed from laptop at “Gregg Base”

There are 5 episodes in total in the “Keepin Britain Going” series, all had their own idiosyncrasies on location but all have been through the edit, in a rapid turn round. Usually ITF has an 8 week edit for a programme. These revisit episodes have around 3, with the edit, viewings, sign off, dub and Online being done remotely. It’s a pretty impressive operation. Also shows the lengths that TV programme makers are going to keep the “Fresh” content coming.

TECH SPEC & CORONA VIRUS

Individually Packaged and Cleaning Radio Mic & Body Recorder Kits.

Just to give you a brief run-down of what I have been doing regards kit cleaning and working in Lockdown.

The standard tech spec for the shoots:

4 x Wisycom Radio Mic Tx

4 x Zaxcom ZFR900 Body Recorders

2 x Peltor Headsets

10 x Cos 11

5 x G3 IEM

1 x G3 IEM TX

1 x Wisycom 42 Rx

1 x Wisycom 52 Rx

1 x Digislate

3 x Ultrasync One

1 x iPad

1 x C stand and Clamp

Day Before Kit Prep:

Pretty much all of this would leave me in the morning, come back at lunch time and then out again for the rest of the shoot from start of afternoon to wrap. So everything would have to be cleaned the day before. With this lot, cleaning and prep took around 1.5 to 2hrs.

All equipment that will be cleaned down with Isopropyl 70% alcohol and anti bac wipes.

Radio Mics with lavalieres, after fresh batteries and frequency/gain structure check go into a Ziplock bang to be handed directly to the wearer, bag is labelled with contributor name to avoid any confusion. Idea is that once the bag is sealed at home it won’t be opened by anyone other than contrib. From there, I talk them through how to mic themselves, we kept things simple for this one, croc clips and Bubblebee windgags.

Zaxcom body recorder with lavaliere mic, same principle, but bag will have to be opened to sync timecode (I don’t use Zaxnet for TC). I wear one set of gloves to open the bag, feed time code, set recording, then wipe down with anti bac wipes the Zaxcom and wire and return to bag. It’s then handed over to the contributor, who will be the only one to wear it.

The Bubblebees were sprayed with the anti bac spray and left to dry. I used one of the proprietary brands that is made to be sprayed and left. Also by prepping the kit as early as possible meant the kit could be left for anything as long as 36hr, all helping to kill any nasties that might have been around the kit.

IEM, the same principle batteries and freq checks, labelled for individual. Headphones either provided by the user or by production for that specific person on that shoot, i.e it comes out of the box for the shoot and goes in the bin at the end. Found some cheap ones on amazon. £3.99

All contributors have separate TX’s and lavalieres, whether they are in the same scene or not. This was something that production and the factory agreed on to minimise passing equipment between people. If I had been allowed in then obviously, I could have cleaned down the kit before moving it on. We didn’t have enough time, or indeed people, inside the factory that could run kit in and out between set ups.

Ie. Tomorrow we have four people across the day, only two sequences where two people will be together but 4 Tx and 4 Zaxcom.

Kit on location @ Essity Factory. iPhone swapped in for iPad. It’s a long story!

Shoot Day:

Any equipment that will be used by others on location, in this case a Digislate and iPad are cleaned and handed over directly to the only person that will use it for the day. No one else can use it, when it’s handed back to me at the end of the day it’s cleaned immediately before being returned to my kit.

All the kit in one case. Bagged and ready for the shoot.

Adding sound kit to camera.

I wore a face covering and gloves when adding the Timecode and Audio Rx. Once kit is on and any menu/settings adjustments made I gave my kit and the screen and buttons a wipe down with Anti Bac and then asked the camera dept to do the same so they are happy, the other option would be offer to stay 2m away and have the operators do it whilst supervised but that would probably be more time consuming. Back at my kit, gloves go in the bin and I give my hands a clean down with either hand wipes or anti bac gel.

Radio Mic’s cleaned, prepped & Bagged.

Mic’ing.

So far all Contribs have been guided on how to mic up. It’s a bit weird and you have to have some patience with it but it’s ok as long as they pay attention.

Once they have the mic on, I encourage them to either use the anti bac hand wipes I have to hand or go wash their hands. I ask them not to play with the mic, cable or pack when it’s on.

I’ve been considering getting everyone to wear belt packs but the need to have then cleaned and then getting the contrib to get them on easily is making me hold on that one.

If I have to mic someone up I’ll wear gloves and a face covering but only if contrib and production are happy with me coming in close to mic.

I haven’t been in a position to have to boom due to no radios but have a feeling that I’ll be using my drama pole more than my short pole with that in mind. Not only to be 2m’s away from contrib but also be able to be 2m away from camera, director and contrib. Good shoulder work out coming?

I’ve got three plastic cases in my car now as part of my PPE/Protocols:

“Green is Clean”………….. Red X Marks the spot? Not as catchy is it!

1 – “Green”, Clean case, All kit in this goes in after being cleaned.

2 – “Red” Dirty Case, after each piece has been used it goes in this case, no bag. It can’t be used again until it’s been cleaned and re-bagged.

3 – PPE Case.

Contains:

Gloves,

Masks (bought by production and pretty useless as you can’t breathe or

speak to anyone)

Ziplock Bags

Anti Bac Wipes

Anti Bac Hand Wipes

Hand Soap

Isopropyl

Kitchen Towel

Anti Bac Spray – for handles on boxes, bags, straps, anything that won't go bang with moisture basically.

The PPE box. Bit of everything, just in case.

The case system is working fine on the current locations as I have a base to work from, namely the car outside the factory, when it comes to more “normal” PSC shoots I’ll have the kit in a back pack, all individually marked in their own Ziplock bags as per the factories shoot, but in a separate pocket on the bag I’ll have a large “Red” bag, just means it’ll all be kept separate and be obvious as what has been used and what hasn’t.

I’m going to start adding the date to the bags as well. Mainly because on some of the shoots I might not know the contributor’s names and so forth. Just another way of being able to see what has and hasn’t been used and when.

Minimising contact while working.

Social distancing has been pretty easy whilst on location as we haven’t been allowed inside the factory due to their protocols, but when I was on location for the Welsh end of the BBC Ident they were all very well versed in it, I think that will be the key for all of us. Getting “programmed” into operating at 2m social distancing. When you’re with people who have been working through the lockdown they do it unconsciously. Like a dance. But then again I don’t know many dances where the participants are 2m away from their partner.

I drive to locations on my own, no difference to normal, audio books are the key – maybe that’s the subject of another blog. I also try and keep stops to a minimum so have a packed lunch and coffee in a flask or made on a JETBoil burner. Sounds a little “Prepper-esque” maybe but it guarantees a good coffee. ;0)

So, on the journey home I can take breaks but not HAVE to use services. I know that the BBC are saying that travel for a job should not be mixed with non-essential travel. Namely don’t pop in for coffee with a mate on the way home from a shoot as he lives on the way.

Working during lockdown and amid the Pandemic is a constantly evolving situation, just something that we are going to have to get used to and keep I eyes on any new information and/or guidelines that come in from the experts.

I hope this blog finds you all healthy and happy and maintaining a positive mental health throughout this very trying time. Hopefully see you all on location soon.

© 2025 Cochyn Sound. All Rights Reserved. Website by Delwedd